Surplus to the Ongoing Operations of Star Thermoplastics & Other Plastic Companies

Broadview, IL

Surplus Plastic Extrusion and Compounding Equipment, Including Compounding System, Twin Screw Pelletizing Line, Single Screw Pelletizing Line, Sheet Extrusion Line, Injection Molding Machines & Ancillary Equipment, Storage Container, Mixer, Tank, Heat Exchanger, Grinders, Feeders, Dryers, Rheometer & Lab Equipment, General Plant, & Much More!

Featuring:

Farrel CP-23 Compounding System Consisting Of: (1) Farrell Compact Processor Continuous Mixer, type CP-23. #2 Cored rotors driven by an 30hp, 500 volt, 1150 rpm DC motor. (1) Farrell approximately 3 single screw extruder, driven by a 20hp, 500 volt, 1750 rpm DC motor thru a Koellmann reducer, ratio 18.27 to 1. Both frame mounted. (1) Approximate 3-1/2" hydraulic screen changer with hydraulic power pack. (1) Farrel control panel with (2) Emerson drives. (2) Acrison feeders with control panels, (1) Gala underwater pelletizing system consisting of: (1) 3hp cutting head, (1) Model 20 gpm water tank, serial# 821050, (1) Model 8.1B.F. spin dryer, serial# 821050, (1) control panel, (1) Witte approximate 16" wide x 44" long screener, serial# 3383.

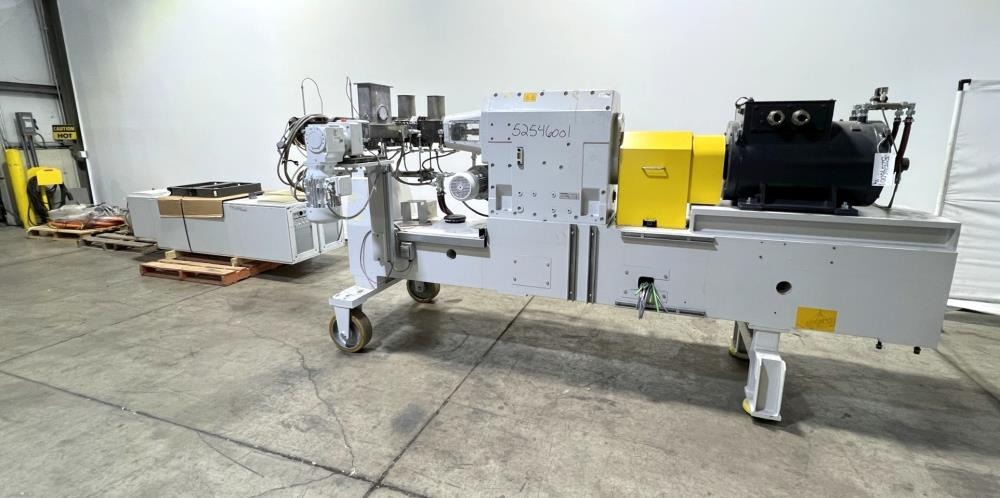

Twin Screw Pelletizing Line

Farrel Twin Screw Pelletizing Line Consisting Of: (1) Farrel 37 mm FTX80 co-rotating twin screw extruder, 5 zone electrically heated, water cooled, approximately 40:1 L/D. Driven by a 25 hp, 500 volt, 1750/2300 rpm DC motor thru a Flender reducer, ratio 1.759 to 1. (1) Control panel with Mentor drive and temperature controllers. Serial# 956129. Includes (1) AEC TCU100-0 temperature controller, (1) Acrison feeder with mezzanine, (1) Gala underwater pelletizing system consisting of: (1) 2hp cutting head, model 5MUP, serial# 890502, (1) Model 20 gpm water tank, serial# 8260554, (1) Model 8.1B.F. spin dryer, serial# 860554, (1) Witte approximate 16" wide x 70" long screener, serial# 4250. (1) NBE tote dumper, (1) hopper with inclined screw feeder.

Single Screw Pelletizing Line

HPM Single Screw Pelletizing Line Consisting Of: (1) HPM 3-1/2'' single screw extruder, Model 3.5TMC, Serial # 88342. Approximately 40 to 1 L/D ratio. Electrically heated, air cooled 6 zone side vented barrel. Water cooled feed throat with an Acrison feeder, model A405-700-125-1015X-G with controller and magnet. Extruder driven by an approximate 150 hp thru a reducer. (1) Extruder control panel with temperature controllers, and drive panel. (1) Gala underwater pelletizing system with cutting chamber, 6MUP cutting head, (1) Gala control panel, (1) 40 GPM water system, (1) Gala spin dryer and a Witte screener.

Sheet Extrusion Line

PE-TECH Matrix Sheet Extrusion Line (2012), Consisting of: PE-TECH Matrix Extruder, S/N PETECH-2012-02, 26:1, 150mm screw, with Screw Cooling, Manual SwingGate, and Screen Changer; (2) PE TECH Control Panels; Mokon Temperature Controller Model HY4C09IL, S/N 7010727; (3) Roll Chrome Upstack Calendar, Upper Roller - 9 1/2" Diameter x 47 1/4" Width, Middle and Lower Rollers (each) - 15 1/2" Diameter x 47 1/4" Width, with (2) Mokon Temperature Controllers Model HY409IL; PE-TECH Edge Trimmer; NDC Center Web Sensor with PLC Touch Controls; PE-TECH Rewinder; 1-Ton Kukdong Gantry Crane with 1-Ton Chain Hoist and Pendant Controls; 1-Ton Spanco Mobile Gantry Crane with 1-Ton Chain Hoist; Small Mezzanine; (3) Spare Dies and (3) Assorted Die Carts, including Die Splitter Cart; and Misc. Spares Parts in Boxes

Twin Screw Extruders

Freesia-Macross NRII 75mm SG Co-rotating Twin Screw Extruder. 40 L/D. Approximate 75mm diameter x 115" long screws. Electrically heated, water cooled. Approximate capacity 500 - 1500 kg/hr. Driven by a 150hp GE KinaMatic Direct current motor, 1750/2000 rpm, 500 volt. Approximate 5" x 4" water cooled feed throat. Twin screw feeder. Approximate 32" centerline height. Drive panel with (11) temperature controllers.

Berstorff ZE62 x 44D 62mm Twin Screw Extruder. Requires approximate 62mm x 104" long screws. 44/1 L/D. Electrically heated, water cooled. (9) barrel heating zones. Driven by Reliance AC 250 HP, 480/3/60 VAC, 3,000 RPM (limited to 242 HP). Flender gearbox, Year 2005, Serial# 4140712-0020-1, Ratio: 5:1. Control panel with Allen Bradley Drive PowerFlex 700S drive. Allen Bradley VersaView 1200P HMI. 4" X 4" Feed throat. Approximate 48" centerline height. Missing Screws.

Leistritz 60mm ZSE MAXX Twin Screw Extruder, Type ZSE60MAXX-20D. (2) Co-rotating screws approximately 2.44" diameter x 62" long. Speed 400 rpm. Approximate 20 to 1 L/D ratio. 4 Barrel sections, 1 feed section. Liquid heated and cooled. 4-Cooling zones. Screws driven by a 121kw (160hp), 1600 rpm motor thru a gearbox. Leistritz model LSB 56 twin screw side feeder, driven by 3.45kW, 3/60/264/460 volt, 1700 rpm gear motor, 5.3 to 1 ratio. Rickmeier pump, driven by a 1.4kW motor, thru Funke plate heat exchanger. Includes drive panel with Siemens Sinamics controller. *No main control panel*. Mounted on frame with wheels and adjustable feet. Serial # 04144, order # 310.1121.01. 3/60/480 Volt, 294 Amp.

Leistritz Twin Screw Extruder, Model MIC 27/GGC-40D. Throughput rates approximate 10 to 80 lbs/hr. 40:1 L/D. (2) Screws approximate 27mm (1") diameter x 48" long, co-rotating. Electrically heated, water cooled. Includes operators panel with Quantum III DC Drive and Eurotherm controllers. Screw rpm 500. 12kW (15hp) DC motor drive. Mounted on casters. Serial# 2567, built 1997. Unit with controls but no barrels.

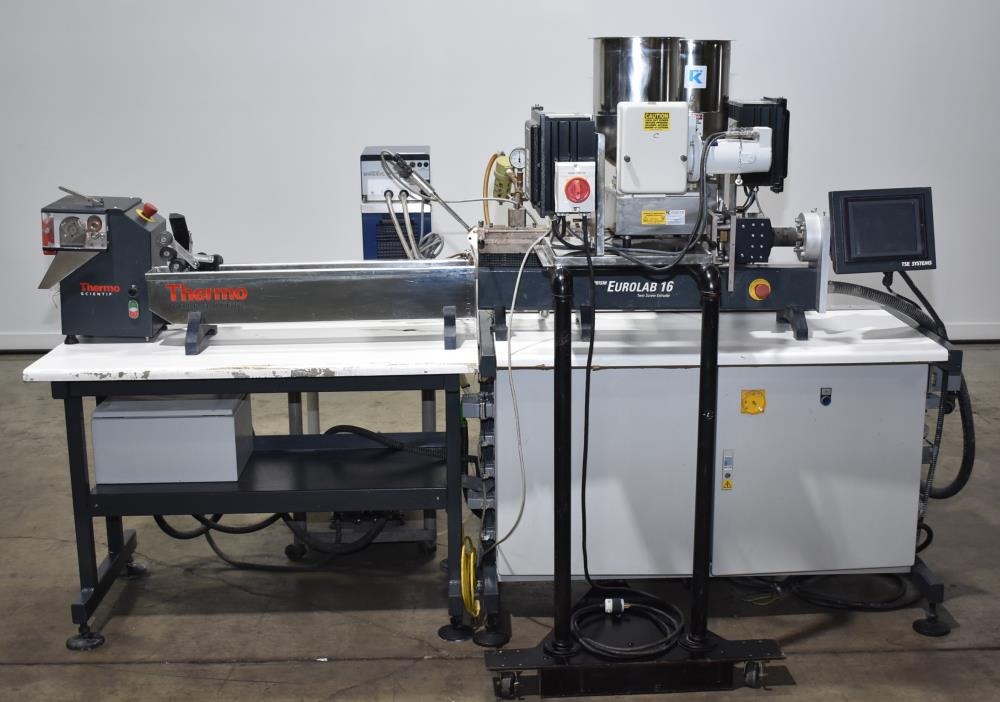

Thermo Electron 16mm Prism Eurolab 16 Bench-Top Co-Rotating Twin Screw Lab Line. Capable of batchers of 50 g up to 10 kg/hr. Consisting of: (1) Co-Rotating 16mm twin screw extruder, 25:1 L/D, electrically heated. Driven by 1.25 kW motor at 500 rpm screw speed. (2) K-Tron model KCL-KT20 twin screw feederS. (1) Water bath. (1) LKB Bromma 2219 multitemp II thermostatic circulator. (1) Zepher .5 kW blower. (1) Thermo Electron Prism pelletizer. Control panel with Omron Sysmec PLC, Omron servo drive, Omron VS mini J7 drives. Tabletop mounted

Single Screw Extruder

Merritt Davis 6" Extruder. 36:1 L/D. Vented barrel with 18" air operated side stuffer. Air-cooled. 600HP DC motor with Control Techniques drive. Control cabinet with Allen Bradley SLC 5/03 PLC and Cutler Hammer Panel Mate HMI. Has original wiring diagrams as well as PLC and HMI programs. Includes: 36" X 36 feed conveyor with new belt. 16" X 16 Feed conveyor with air ram and new belt. Condex hot face cutter, 6 accessory drives for upstream and downstream equipment. Rebuilt barrel and screw

Injection Molding Machines & Ancillary Equipment

(5) Arburg Injection Molding Machines

Injection Molding Machine Robot

Assorted Temperature Controllers

High Intensity Mixers

Mitsui Mike High Intensity Mixer, 700 Liter Capacity, 304 Stainless Steel. Approximate 36" diameter x 42" deep jacketed bowl. Jacket rated 5 kg/cm2 (71 psi). Two tier bottom blade driven by a 75hp, 3/60/208-230/460 volt, 1780 rpm motor. Swing away top cover. Side bottom outlet with plug valve. Mounted on a painted carbon steel base. Serial # FM500656.

Mixaco High Intensity Mixer, Model CM1000, Stainless Steel. Max working capacity 800 liter (28.25 cubic feet), total capacity 1000 liter (35.3 cubic feet). Rotating mixing chamber with cone bottom. 1-Tier mixing blade driven by 22kW (30hp) 3/50/380 volt 1400/81 rpm gear motor. Center bottom outlet. Pneumatic tote locking lugs. Rotating motor approximate 2.2kW. Mounted on base. Serial# 22574. Applications include powder coating, master batch, dye concentrates, toner, PVC, metal compounds, PTFE, silicic acid, food, cosmetics, brake linings and pencil leads.

Henschel Fluidizing Mixer; Model FM-10; 304 Stainless Steel. Approximate 9" diameter x 8" deep. Driven by a 5hp; 3/60/230/460 volt; 1750 rpm motor. Approximate 3-1/4" outlet with valve. Has Reliance GV3000/SE AC Drive. Mounted on casters. Serial #001083. New controls required.

Mitsui Miike 700 Liter High Intensity Mixer; Model FM700F; 304 Stainless Steel. Approximate 32" diameter x 42" deep jacketed bowl. 570/285 RPM Blade Revolution; Driven by a 55/27.5 kW (74/37 HP) Motor. Top openings: (3) 5"; 6"; 10"; 12" side bottom outlet. Machine # FM500598

Mitsui Mike High Intensity Mixer; 700 Liter Capacity; 304 Stainless Steel. Approximate 36" diameter x 42" deep jacketed bowl. Jacket rated 5 kg/cm2 (71 psi). Two tier bottom blade; driven by a 75hp; 3/60/208-230/460 volt; 1780 rpm motor. Swing away top cover. Side bottom outlet with plug valve. Mounted on a painted carbon steel base. Serial # FM500684.

Mitsui Miike 700 Liter High Intensity Mixer; Model FM700F; 304 Stainless Steel. Approximate 32" diameter x 42" deep jacketed bowl. 570/285 RPM Blade Revolution; Driven by a 55/27.5 kW (74/37 HP) Motor. Top openings: (3) 5"; 6"; 10"; 12" side bottom outlet. Machine # FM500598.

Farrel Banbury Mixer

Tank

Letsch Jacketed 188 Liter Stainless Tank

Heat Exchanger

Alfa-Laval plate heat exchanger

Belt Pullers

Xintian Machinery 800mm Wide x 2400mm Long Contact Dual Lane Cleated Belt Haul Off Unit; Serial# 201400068; Built 2014.

Boston Matthews 2 Belt Puller, 4.25"x 24" Belts

Vacuum Calibration Tables

JWell Extrusion Machinery Vacuum Calibration Unit. Shaping range 0-1400mm; effective length 5000mm; Serial# MP1411/174.

Xintian Machinery 800mm Wide Vacuum Calibration Table; Serial# 201400067; Built 2014.

Cut-Off Saws

Boston Matthew Cut-Off Saw Model AS75, S/N 4620

Boston Matthew Cut-Off Saw Model AS75, S/N 1132

Grinders

(7) Grinders

Feeders

(17) Acrison Feeders

AccuRate feeder

K-Tron Feeder

Dryers

Una-Dyn Dryer

Rheometer & Lab Equipment

Kayeness Capillary Rheometer

Fume Hood

Storage Container

Suihe M45G3QC 40' High Cube Open-Sided Storage Container

General Plant

Assorted Hydraulic Power Packs

Assorted Motors

Assorted Hoppers

Barrel Dumper

Assorted Transformers

Assorted Valves

Assorted Stainless Totes

Power Washer

Battery Chargers

And Much More!