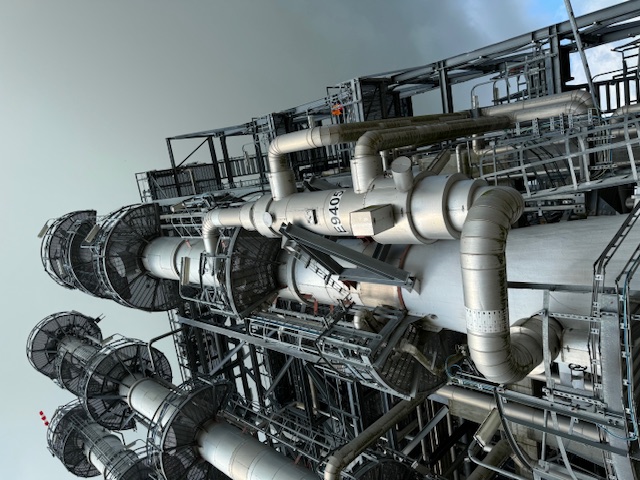

Orsted, Danish Oil Pipe - Crude Oil Stabilisation Plant

Fredericia, DNK

153,000bpd Crude Oil Terminal Stabilisation Plant comprising: Degasser Unit (Unit 9600) with Heat Transfer Unit, Gas Plant (Unit 9400), and Liquid Gas Treating Unit (Unit 9330)

Offers Invited for Immediate Sale - 153,000 Barrels per Day

153,000bpd Crude Oil Terminal Stabilisation Plant

Degasser Unit (Unit 9600) with Heat Transfer Unit,

Gas Plant (Unit 9400), and

Liquid Gas Treating Unit (Unit 9330)

Degasser Unit (Unit 9600) in two parallel trains

Request Process Flow Schemes 9600/09/010 to 9600/08/015

Degasser

Live Oil/Stabilised Oil heat exchanger E-9605A/C/E/G

Live Oil/Heat Transfer Fluid heater E-9604A

Flow control valve

Degasser Vessel V-9601

Offgas routed to 1st Stage of Compressor K-9601A

Stabilised Crude Pump P-9615A

Degasser Water Pump P-9616A

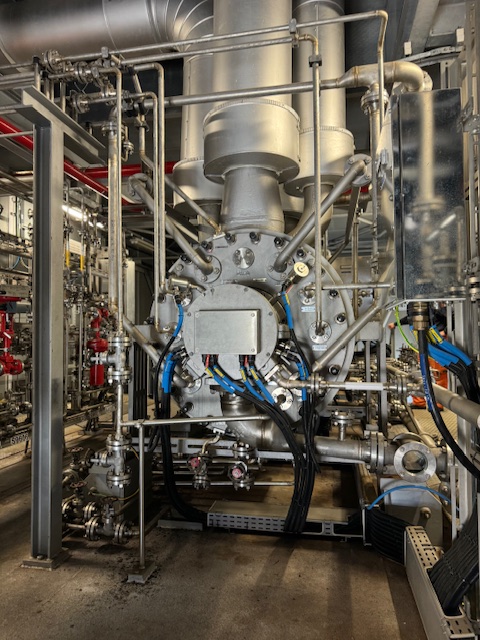

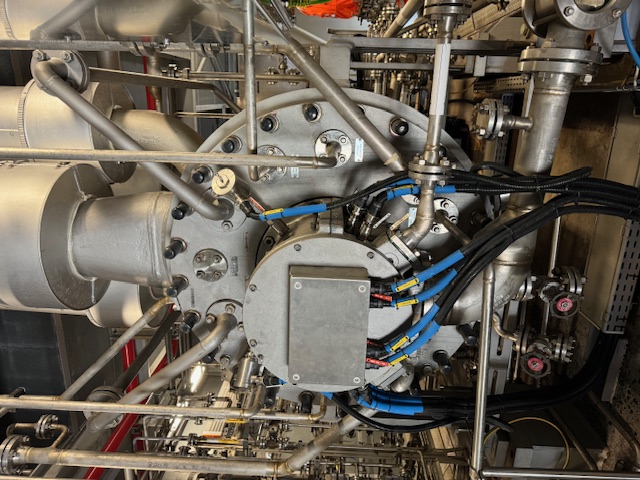

1st Stage Compressor

1st Stage KO Drum V9605A

Fixed speed, two stage centrifugal Compressor K-9601A

Control valve

Anti-surge Spillback (routed to inlet of Degasser Vessel) with Air Cooler E-9609A

1st Stage Condenser E9607A

1st Stage Separator V-9606A

Condensate Pump V-9617A

2nd Stage Compressor

Control Valve

2nd Stage KO Drum V-9607A

2nd Stage Compressor

2nd Stage Condenser E-9608A

2nd Stage Separator V-9608A

Offgas line control valve

Naptha Stream Pump P-9618A

Liquid Butane Product Cooler E-9302

Gas Plant Unit (Unit 9400)

Request Process Flow Scheme 9400/08/001 to /003

Stabiliser

Stabiliser Feed Preheater E-9401

Stabiliser Column C-9401

Stabiliser Reboiler E-9402

Naptha Rundown Cooler E-9404

Stabiliser Overhead Condenser E-9403

Stabiliser Overhead Accumulator V-9401

Stabiliser Reflux Pup P-9401

Stabiliser LPG Pump P-9402

Deethaniser

Deethaniser Column C-9402

Deethansier Overhead Condenser E-9406

Deethaniser Overhead Accumulator V-9402

Static Mixer M-9401

Deethaniser Reflux Pump P-9403

Deethaniser Reboiler E-9405

Depropaniser

Depropaniser Columns C-9403

Depropaniser Reboiler E-9407

Butane Rundown Cooler E9409

Depropaniser Overhead Condenser E-9408

Depropaniser Overhead Accumulator V-9403

Propane Product/Reflux Pum P-9404

Liquid Gas Treating Unit (Unit 9300)

Request Process Flow Schemes 9300/08/001 to 9300/08/002

Liquid Propane Treating U-9301

6x identical Adsorber Vessels V-9301A/B/C/D/E/F in series, each with zinc bed adsorbent, 4+2 lead-lag adsorber vessel configuration

Propane Rundown Cooler E-9301

Propane Product Storage Tanks

Cooling Water Circuit, also used for Butane, comprising

Cooling Water Tower A-9301

Water Softening Unit incl. Water Softener A-9302, NaCl Storage Tank and Resin Trap A-9305

Chemical Injection Skid

Circulation Pumps P-9302A/B

Cooling Water Filter S-9301

Adjacent piping and equipment

Liquid Butane Treating Unit (Unit U-9302)

6x identical Adsorber Vessels V-9302A/B/C/D/E/F in series, each with zinc bed adsorbent, 3+3 led-lag configuration

Butane Rundown Cooler E-9302

Butane Product Storage Tanks

Heat Transfer Fluid (HTF) Unit (Unit 9600)

Request to Process Flow Schemes 9600/08/016, /017 & /035

HTF Heating System

Expansion Vessel V-9610

HTF High Temperature (HT) Circulation Pump P-9620

HTF Furnace F-9601

HTF HT Supply Header

HTF HT circulation loop includes Trim Cooler E-9612

HTF Low Temperature (LT) Circulation Pump P-9621

Side Stream Filter S-9622

Start-up Cooler E-9611

HTF Furnace F-9601, gas fired

with 6x low NOx forced draught burners

and 2x Forced Draft Fans K-9605A/S

Induced Draft Fan K-9606

Air Preheater E-9610

Flue Gas Cooler E-9613

LP Fuel Gas KO Vessel V-9625

HTF Drain System

Request C750-CBIH-P-RA-0058 Process Description HTF Storage and Drain System.